Benelli Raffaello Black

2.096,00 € Original price was: 2.096,00 €.1.886,40 €Current price is: 1.886,40 €.

ΚΩΔΙΚΟΣ ΕΙΔΟΥΣ: 0000102076

Dispatch in 4 - 10 Days

Benelli Raffaello Black

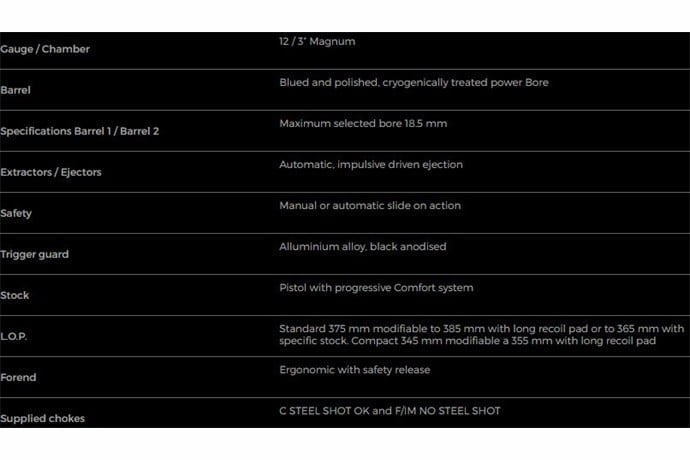

Gauge: Ga 12-3″

Stock and fore-end: Oil finished grade 2 walnut with new Progressive Comfort system

Recoil pad: Special polyurethane

Chamber: 76 magnum

Mechanics: Semi-automatic shotgun with inertia driven geometric locking and rotating bolt

Receiver: Nickel plated receiver, bolt unit machined from billet and chrome plated

Comb: Special Polyurethane

Stock length trigger measured / deviation: 365 mm / LH and RH adjustments

Drop at comb: 37 ± 1 mm

Drop at heel: 55 ± 1 mm, adjustable to 45/50/60/65

Weight: Approx. 2,900 g with 70 cm barrel

Magazine: Without plug: 3 rounds of 12/76, 4 rounds of 12/70. With plug; 2 rounds.

Safety: Enlarged transverse with red ready to shoot signal

Trigger guard: Technopolymer – chrome plated

Trigger: Removable trigger unit; trigger weight from 22 to 28 N; reversible, transverse safety; automatic anti-repeat device, automatic locking device to prevent firing unless the bolt is fully retracted; magazine cut-off

Sight: Red fluorescent

PROGRESSIVE COMFORT:

The new system of progressive absorption of recoil that occurs in a gradual way based on the weight of the cartridges used. That is the true essence of comfort in the wood, a system invisible but highly sensitive.

INERTIA DRIVEN SYSTEM:

Essential design, simple construction, easy maintenance and mechanical precision for maximum strength and reliability.

The cleverness of the Benelli System lies in the rigor of its design, constructional simplicity and ease of maintenance. There are three main components: the bolt, that acts as an inertial mass and slides freely along guides made in the sides of the receiver, the locking head and the large free spring, mounted on the bolt.Its operations is ingenious and efficient. While the bolt assembly moves into the firing position, the locking head pin movesalong a shaped guide inside the bolt to engage the locking head.When the trigger is pulled, all the components of the shotgun,with the exception of the bolt, move backwards. At the same time,the inertial spring is compressed between the head of the bolt and the body of the bolt itself. The cartridge drop lever rises to allowthe cartridge to move from the magazine to the firing chamber.Towards the end of the recoil cycle, the pressure inside the chamberreaches a safe level and the backward movement of the shotgun slows down. Then, the heavy inertial spring pushes the bolt assembly backwards, releasing the revolving head of the bolt and extracting the cartridge fired from the chamber, pushing it against the ejector. When the empty cartridge leaves the receiver, the energy developed by the moving bolt assembly rearms the hammer and compresses the recoil spring inside the stock. Following this, the recoil spring pushes the bolt assembly forwards, in this way raising the shell forwards into the correct position and putting a new cartridge into the chamber. The brevity and ease of these movements together with mechanical precision and constructional simplicity guarantee an operating cycle which will not alter or jam, offering maximum resistance and extreme reliability.

INERTIA DRIVEN SYSTEM:

| Weight | 3,5 kg |

|---|---|

| Κατασκευαστής |

Related products

Airgun Handguns

Airguns Rifles